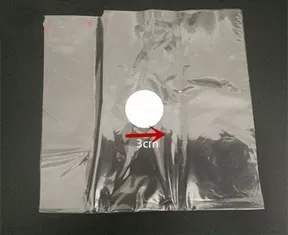

Aseptic Breathable Sealing Film Aseptic Culture Container Sealing Film

Description: PTFE bacterial membrane is a high-tech product tissue film. Its microporous main body network structure is obtained by puffing and stretching with a low molecular weight PTFE resin. The opening rate is over 85%. The pore size is 0.3μ. With a temperature resistance of up to 300 ° C, it has a very high elasticity and outstanding hydrophobicity. The unique waterproof and breathable properties reduce the pollution rate to zero. It has unexpected effects as a bacterial filter material in the engineering field. The base film is a composite film of PP unstretched material with a thickness of 0.06 mm. The light transmittance is over 95%. Use the principle of commonality. The PTFE film was firmly welded to the PP film by high-frequency welding automatic bonding technology. The sealing film is made of high temperature resistant material and can be repeatedly sterilized (use more than 20 times). It has good air permeability; it is mainly used for sealing of various kinds of tissue culture bottles of wide mouth, which can ensure that air exchange does not have powdered Egyptian mold. In the bottle, the purpose of sealing and antibacterial is achieved. This re-use rate has been greatly improved, while reducing production costs.

Quantity: 500 sheets / volume

Specifications: 12*12cm/14*14cm/16*16cm , 12*12cm/16*16cm

Filter membrane diameter: ordinary 16mm , 30mm

Filter pore size: 0.2--0.3um

Air flux (M3/m2. hr@p=0.01MPa)=1020

The parameters are as follows:

| Model |

Size |

Filter |

Air permeability |

Operating temperature |

Packing |

| 12# |

120mm*120mm |

16mm/30mm |

85﹪ |

Less 135℃ |

500pcs |

| 14# |

140mm*140mm |

500pcs |

| 16# |

160mm*160mm |

500pcs |

| |

|

|

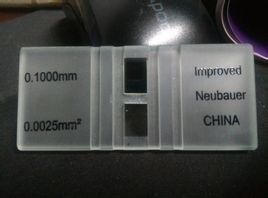

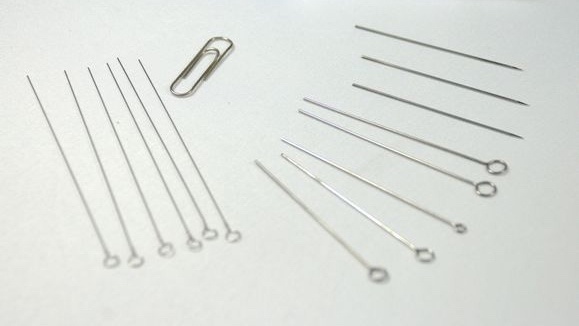

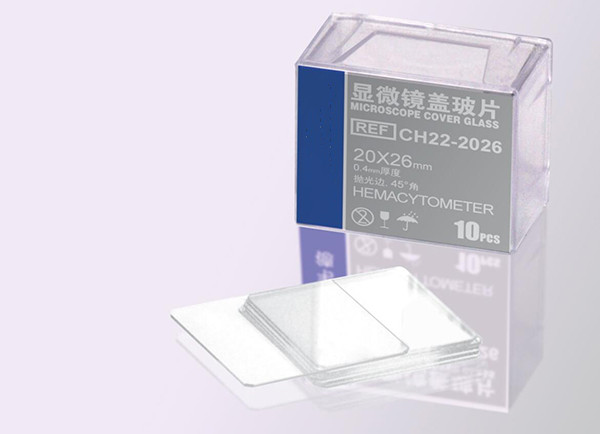

Petri Dish

Petri Dish Histology/Pathology

Histology/Pathology